Solution

We provide the customize solution according to your technology and process requirements!

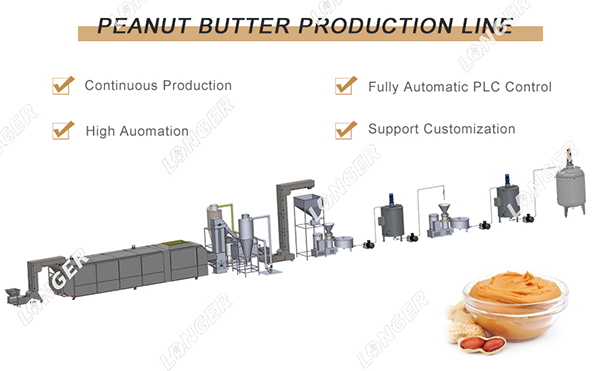

Schematic Diagram of Automatic Peanut Butter Production Line:

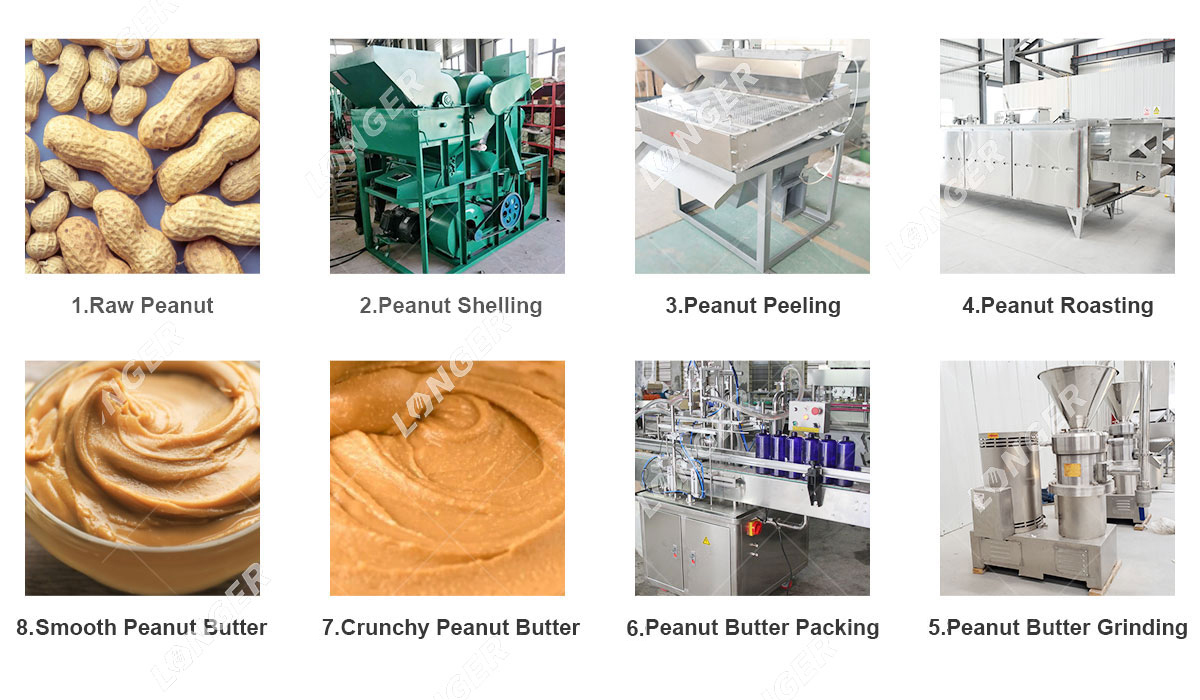

Production Process: raw peanuts(groundnuts) - stone removal - roasting and cooling - peeling - grinding - dressing - grinding - degassing - filling - capping - sealing - labeling - peanut butter

Introduction of 1000KG/H Peanut Butter Production Line:

◆ Peanut Roasting Machine: This machine is equiped with temperature and time control device, can control the quality of the roasted peanuts, which affects the quality of peanut butter.

◆ Cooling Conveyor: Ensure continuous production but also play an important role in cooling roasted peanut kernels.

◆ Roasted Peanut Peeling Machine: This peeler adopts the method of rolling and peeling, suitable for processing peeled peanuts with various specification.

◆ Peanut Butter Grinding Machine: Specialized used for grinding peeled peanuts into butter, Can be single grinder or grinder combination for large peanut butter production.

◆ Mixing Tank: This mixer tank is used for mixing peanut butter with other ingredients such as powdery, salt, sugar, dry skin milk, etc. it also have function of cooling peanut butter.

◆ Vaccum Degassing Tank: This vacuum degassing tank can remove the air from the peanut butter to make it more stable and can be stored for longer time.

◆ Storing Tank: This storing tank plays a part in storing and cooling peanut butter, preparing for the filling and packaging of peanut butter products.

◆ Peanut Butter Packaging Machine: This packing machine is used to package the peanut butter into finished peanut products for sale.

Advantages of Automatic Peanut Butter Processing Line:

★ The whole line has clear process flow, complete functions and advanced equipment to ensure the quality of peanut butter.

★ The core equipment roaster machine ensures the maturity of the roasting of the material, thereby improving the quality of the peanut butter product.

★ The centralized control cabinet or PLC controller can easily control the operation of the whole set of equipment.

★ The closed and unmanned operation ensures that the product quality meets the conditions of food hygiene production.

Share This Post,Choose Your Platform!